Web Cleaning Technologies

Stewarts of America specializes in precision perforating equipment and tooling, where the very process of perforating a web can often generate debris such as dust, chads, and fibers.

Proven Expertise in Web Cleaning Technologies

Other particulates are also possible from anvil rollers used… brush rollers, rubber rollers, silicone rollers, felt rollers, sponge rollers or even sources outside of the direct environment.

Left unaddressed, these contaminants can accumulate on the web surface, transfer into downstream processes, and compromise the quality of the finished product.

To help solve this challenge, Stewarts of America offers web cleaning technologies that are designed to remove debris directly after the source.

By integrating cleaning systems and detection systems downstream with perforating operations, customers benefit from:

- Cleaner Webs – Debris is eliminated before printing, coating, or laminating, reducing the risk of visual defects and adhesion failures.

- Reduced Waste – Removing contaminants minimizes rejected rolls or sheets, lowering material costs and improving first-pass yield.

- Improved Equipment Performance – Web cleaning protects rollers, dies, and slitting equipment from premature wear caused by abrasive particles.

- Compliance with Industry Standards – Clean, defect-free surfaces meet the strict requirements of packaging, medical, and electronic applications.

By combining perforating expertise with advanced web cleaning solutions, Stewarts of America help customers achieve precision perforations AND contamination-reduced results, delivering higher quality products with greater efficiency.

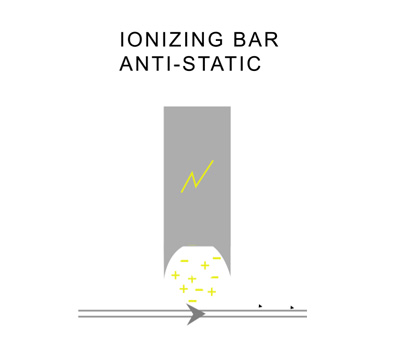

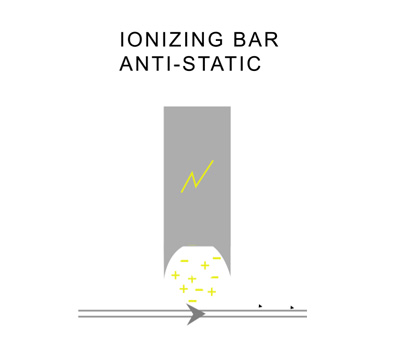

Ionizing (Anti-Static) Bars

Electrostatic control devices used to neutralize static electricity on the surface of materials. These are commonly installed in manufacturing and converting environments where non-conductive materials generate static during processing. The ionizing removes static charge collected by the processing of the material, which helps dislodge debris.

Stewarts of America can provide an ionizing system that is specifically tailored for the requirement, taking the following into consideration

Positioning – Ionizing bars should be mounted close to the charged web, usually 1–6 inches away, depending on the bar type.

Width – A verity of bar widths can be used, and multiple bars can be used in series if required.

Grounding – Proper grounding of the bar and associated equipment is essential for safe, effective operation.

Air Assistance – Some bars incorporate compressed air or fans to extend ionization range or improve coverage in wide-web applications.

Maintenance – Regular cleaning of emitter pins or electrodes is required to maintain performance.

Contact us for more info on Ionizing Bars

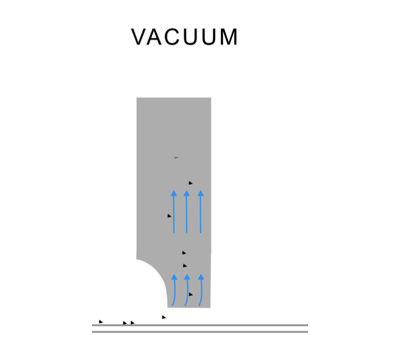

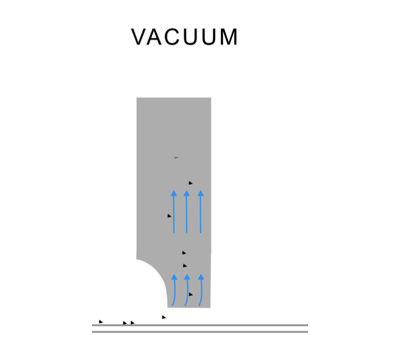

Vacuum Systems

A vacuum debris removal system is an engineered solution designed to extract loose particles, dust, fibers, and other contaminants from a continuously moving web. Vacuums help increase quality, reduce defects, and extend equipment life. The vacuum system creates a controlled low-pressure zone directly above or below the moving web. As the web passes through the extraction zone, debris such as loose chads that have been removed from the material are drawn away from the surface into a ducted vacuum plenum. The removed contaminants are conveyed into a collection unit, typically a filtration chamber, dust collector, or central vacuum system.

Vacuums are not limited to removing debris from webs. Vacuums can also be used for:

Trim Removal – Continuous suction efficiently removes edge trim, matrix waste, and offcuts from slitting, die-cutting, and sheeting processes.

Web Conveyance – Vacuum rollers, tables, or belts stabilize and guide lightweight or slippery substrates, improving registration and reducing misfeeds.

Waste Handling – Centralized vacuum systems transport scrap to collection bins or compactors for easier recycling or disposal.

High-Speed Printing and Packaging – Maintains sheet or web alignment during rapid acceleration or deceleration.

Contact us for more info on Vacuum Systems

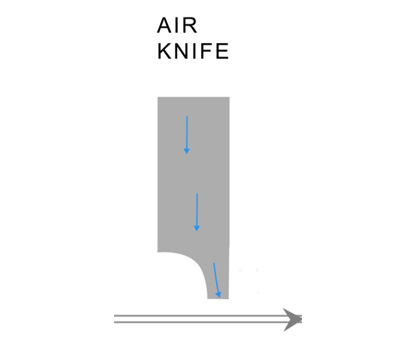

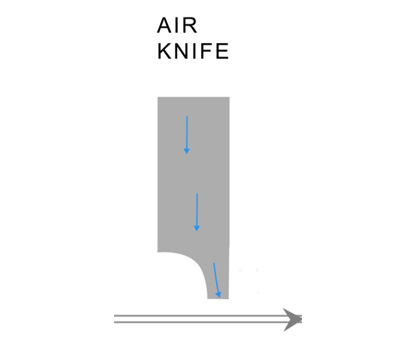

Air Knives

Air Knives generate a high-velocity, uniform sheet of air, used to blow off, clean, dry, or cool materials as they pass through a process line. It is widely used in converting, packaging, printing, food processing, and electronics industries. The air knife produces a controlled, laminar curtain of compressed air or can be blower-driven. As the web passes through the air stream, debris is dislodged from the surface. The loosened particles are then carried away by the airflow or the air knife can be combined together with a vacuum positioned downstream.

Air knives are not limited to removing debris from webs. Air knives can be also used for:

Drying – Eliminates water, solvents, or treatment residues after washing, coating, or adhesive application.

Cooling – Rapidly reduces the temperature of substrates or adhesives before winding or secondary processing.

Web Control – Stabilizes lightweight materials, prevents flutter, and assists with precise web guidance without mechanical contact.

Static Reduction – Often used in tandem with ionizing bars to remove static-charged debris.

Contact us for more info on Air Knives

Brush Roller

A brush roller system uses a bristled cylinder to clean, condition, or modify the surface of a continuously moving web. Stewarts of America offer a number of brush types and configurations, that can remove debris and surface contamination or alter the web surface or texture for functional or aesthetic purposes. The brush roller typically rotates in the opposite direction of the moving web. As the web passes over or under the roller, bristles mechanically engage the surface. Cleans by sweeping away dust, fibers, or loose particles. Brush rollers are often in combination with a vacuum extraction systems to capture dislodged debris.

Brush rolls may operate dry, with vacuum assistance, or in combination with static elimination systems for enhanced performance. Brush rollers are not limited to removing debris from webs. Brush rollers can also be used for:

Smoothing - Smooth and spread materials to eliminate wrinkles or folds.

Control - Provide controlled friction to guide or stabilize webs.

Preparation - Prepare surfaces for coating, texturing, laminating, or printing by ensuring cleanliness and uniformity.

Contact us for more info on Brush Rollers

Sticky Roller

A sticky roller system is a contact-based web cleaning solution designed to remove loose particles, dust, fibers, and surface contaminants from a continuously moving web. By using a tacky roller surface, the system captures debris directly from the web without damaging or altering the substrate. The sticky roller is brought into light contact with the moving web. As the web passes across the roller, particles adhere to the tacky surface of the roller instead of remaining on the substrate. The roller is then continuously or intermittently cleaned using an adhesive sheet, cleaning blade, cleaning roller or washing unit.

Single-Sided Cleaning – One sticky roll cleans one surface of the web.

Dual-Sided Cleaning – Sticky rolls above and below the web clean both surfaces simultaneously.

Continuous Systems – Use peel-off adhesive sheets or replaceable rolls for uninterrupted production.

Sicky rolls can be used in a verity of cleaning applications:

Film & Foil Converting – Removes dust and static-attracted debris from plastic films, aluminum foils, and metallized substrates.

Paper & Board Processing – Cleans fine dust and fibers that could interfere with coating or printing.

Lamination Lines – Prepares surfaces by ensuring contaminant-free contact between layers.

Printing & Packaging – Improves ink adhesion and reduces print defects.

Cleanroom Converting – Critical in electronics, medical, and optical applications where surface contamination cannot be tolerated.

Contact us for more info on Sticky Rollers

Stewarts of America also offer perforator auxiliary equipment such as:

Quick Change Tooling Stand

Stewarts of America have developed a Quick Change Tool Stand to reduce downtime between perforating tooling changeovers. The stand is a precision mechanical assembly designed to facilitate rapid and accurate swapping of tooling components, such as pinned segments, pinned ring and sleeves, knives and blades for the converting machinery. The quick change stand minimizes machine downtime, and improves operational efficiency by enabling operators to change tools quickly without extensive adjustments or recalibration. Operator safety is also enhanced my minimizing handling and supporting the rolls with a strong and sturdy mechanical support that can be rolled around for mobility.

Contact us for more info on Quick Tooling Change Stand

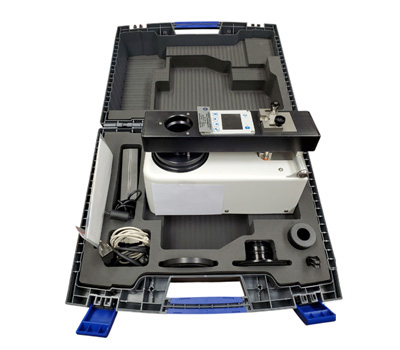

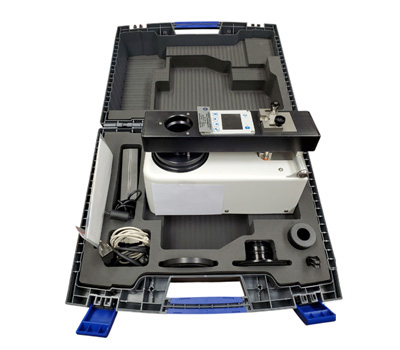

Perforation Testing Equipment

Once perforating the material is complete, a testing device to quantify the results. Stewarts of America offer compact, precise testing machinery for the testing of perforation and permeability in a material. This equipment allows the operator to monitor, record and most importantly quantify results of the creation of nano, micro or macro perforations or slits in various flexible materials such as films, papers, foils, nonwovens, and laminates. Some of the devices Stewarts of America can create simulate consumer requirements on a small scale, and others offer precision readings and analysis, allowing material scientists and engineers to evaluate perforation patterns, hole sizes, densities, and their impact on resulting material properties before or during full-scale production.

Contact us for more info on Perforation Testing Equipment

Brush Roller Cleaning Unit

Stewarts of America brush roller cleaner is a bristle brush-cleaning device that uses an adjustable speed motor to rotate the brush and has an adjustable blade that makes physical contact with the bristles. The mechanical action of the cleaning blade lifts and vacuums away debris from the brush bristles. Collected debris is then removed using an upper vacuum system for lightweight debris, and lower vacuum for debris that falls. The dual vacuum system ensures that debris is effectively removed from the chamber and not re-deposited onto the web or surrounding components. The enclosed housing prevents debris from escaping into the environment. Continuous vacuum extraction maintains a clean operating zone and extends brush life.

Contact us for more info on Brush Roller Cleaning Unit

A Global Leader in Technical Textiles and Precision Perforating