Industrial Rolls

Industrial rollers are a critical component in a wide range of converting, packaging, printing, laminating, coating, and material-handling applications.

As a manufacturer of precision-engineered rollers, the goal is to deliver high-performance solutions that optimize material flow, maintain tight tolerances, and extend operational life.

Stewarts of America rollers are custom designed to meet specific process requirements, whether that involves controlling web tension, applying coatings, ensuring smooth transport, or providing surface finishes for specialized applications. Manufactured from high-quality materials each roller is engineered to provide consistent performance under demanding industrial conditions.

By combining advanced manufacturing techniques with rigorous quality control, we ensure that every roller contributes to reduced downtime, higher line speeds, and superior product quality. Rollers are manufactured to exact tolerances using advanced CNC machining, static or dynamic balancing, and finishing or coating methods. Each roller can be engineered with custom dimensions, surface finishes, and mechanical properties to meet the requirements of high-speed and high-precision operations.

Key construction features include:

- Core Materials: Steel, stainless steel, aluminum, polymer or composite for strength and weight optimization.

- Coverings: Rubber, polyurethane, cork, brush, or specialty machining or coatings for traction, grip, or resistance to chemicals and heat.

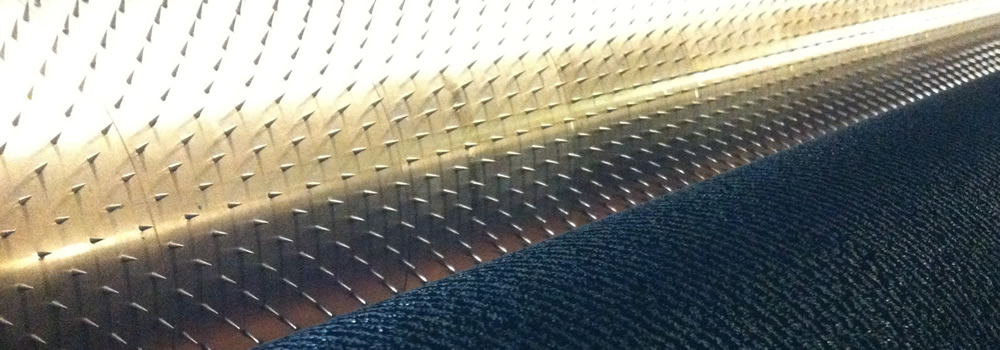

- Surface Treatments: Chrome plating, Teflon coating, anti-slip coatings, knurling, and grooving for specialized functions such as release properties or web tracking.

- Balancing: Dynamic and static balancing to minimize vibration and support high rotational speeds.

- Bearings & Journals: Machined for precision fit, ensuring smooth rotation and long bearing life.

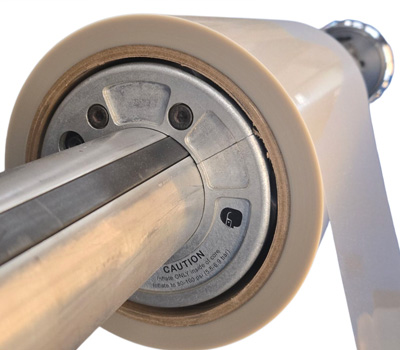

Air Expanding Shafts

A mechanical device used to grip and hold rolls of material in converting machinery. It uses pneumatically actuated elements—typically lugs, bladders, or strips—that expand to grip the core of a roll securely for high-speed rotation or tensioned web handling. These air shafts can also be used for center shafts for cold pin perforating applications.

Lug type – metal or rubber lugs provide strong point contact.

Leaf type – segmented leaves provide full circumferential grip. Strip/rubber tube type – continuous expansion for light to medium loads. This technology can be utilized with Stewarts of America

HIDE-A-SPIKE™ perforating technology that allows a pinned perforating roller to be converted into an idler by retracting the pins.

Stewarts also offer shaft adapters, a cost-effective and practical solution for adapting a standard air shaft to accommodate larger diameter cores. Built from high-quality materials, our chuck adapters are designed to withstand demanding workloads. Their heavy-duty construction ensures reliable performance in both rewind and unwind applications, making them ideal for handling rolls with metal, fiber, or cardboard cores.

Contact us for more info on Air Expanding Shafts

Bow Rolls

Bow rollers are engineered with a precision-curved shaft that creates the spreading action as the web passes over the roller. The amount of spreading can be adjusted by changing the roller’s angle of orientation relative to the web path. A few of the reasons to utilize a bow roller:

- Wrinkle Removal: Smooths webs to reduce defects and downstream issues.

- Web Separation: Keeps slit webs properly apart during winding.

- Adjustability: Bow angle can be fine-tuned to different materials and process conditions.

- Improved Efficiency: Reduces waste caused by misaligned or wrinkled material.

- Versatility: Works with a wide range of substrates including paper, film, foil, textiles, and nonwovens.

Contact us for more info on Bow Rolls

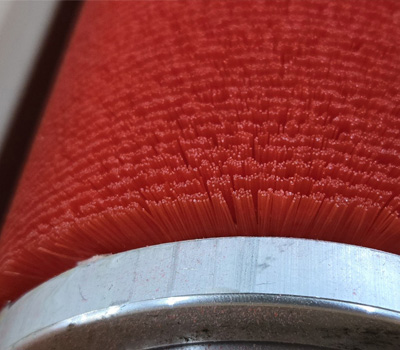

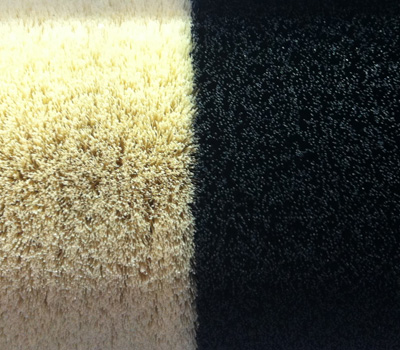

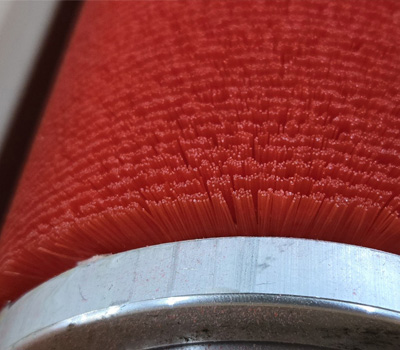

Brush Rolls

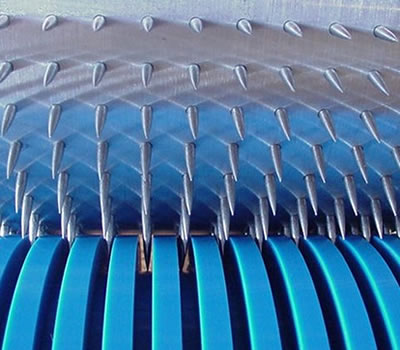

"Superdense" brushes are unlike any regular brush you can envision - They are specially designed for perforating applications, with "superdense" bristle density.

Multi-wall bag and plastic web manufacturers are replacing urethane and felt roller with superdense brush rollers. Superdense brush innovation has improved the process of pin perforating, slit perforating and slitting plastic webs and board products dramatically. Two materials are typically used for perforating, Tampico fibers for hot perforating because of tampico's high temperature resistance, and Nylon for cold perforating, slitting or any other operation at room or low temperature. Positives of this technology is that the brushes extend pin life dramatically over a urethane, silicone or rubber covered roller, as the bristles deflect from the pin tips when penetrated. These bristles move together and provide a solid surface for the web. Another benefit is that it does not matter where the pins engage the brush roller. The brush can accept the pins or blades any location. This reduces setup time dramatically. It is important to note however, that the brush fibers can liberate from the roller, however, so it is important that the user has particle detection equipment downstream of the brush roller.

Superdense brushes offer:

- Superior slitting and perforation quality

- Kind to materials

- Bristles accept pins or blades without with little to no bristle damage

- Dramatically reduces setup and changeover times

- Adjusting the anvil roller to suit the perf roll or blade is completely eliminated, making misalignment impossible

- Excellent web support

- Economical

- Increases pin and blade life dramatically

- Brushes are recoverable

Contact us for more info on Brush Rolls

Brush Spreader Rolls

A Brush Spreader Roller is a specialized roll used in web handling and converting processes to prevent wrinkling, eliminate creases, and maintain proper material alignment during production. Unlike rubber or bowed rollers, the brush roller uses thousands of flexible bristles to gently spread the web, applying controlled lateral forces across its width. This design makes it especially effective for delicate, stretchable, or sensitive materials where traditional mechanical spreaders may cause damage.

- Angled Bristle: The angled bristle pattern exerts a slight outward force on the moving web.

- Spreading action: As the material contacts the rotating brush roller, the bristles distribute the web evenly across its width. This spreading action reduces slack edges, curl, or wrinkles without introducing scratches, deformation, or static buildup.

- Gentle Handling: Ideal for thin or fragile substrates that could tear or stretch under harder spreader rollers.

- Versatile: Works across a wide range of web types and thicknesses.

- Wrinkle Control: Minimizes web creases and bagging without requiring bow or concave roller geometry.

- Low Maintenance: Bristles are durable, self-cleaning in many cases, and resistant to buildup.

- Non-Marking: Prevents scuffs or scratches on sensitive surfaces.

Contact us for more info on Brush Spreader Rolls

Cork Covered Rolls

A cork covered roller is a specialized roll used in converting processes where controlled friction, cushioning, or non-marking contact with web materials is required. The cork covering provides a natural, compressible, and durable surface that enhances grip without damaging delicate substrates. Cork covered rolls have a naturally high coefficient of friction and provide excellent traction for web control without slippage. Cork is non-marking and gentle on sensitive materials, reducing risk of scratches or impressions. Cork has good thermal Resistance.

Cork rolls are commonly used for Pull/Gripping/Traction Rolls and anvil rolls.

- Cork Surface Layer: Natural cork is selected for its compressibility, resilience, and slip-resistant properties. The cellular structure of cork allows the roller to absorb pressure and conform slightly to uneven surfaces.

- Adhesion to Core: The cork is bonded securely to a metal or composite core to ensure durability under continuous industrial use.

- Custom Hardness: Cork density and thickness can be adjusted to suit specific converting operations, balancing grip with cushioning.

Contact us for more info on Cork Covered Rolls

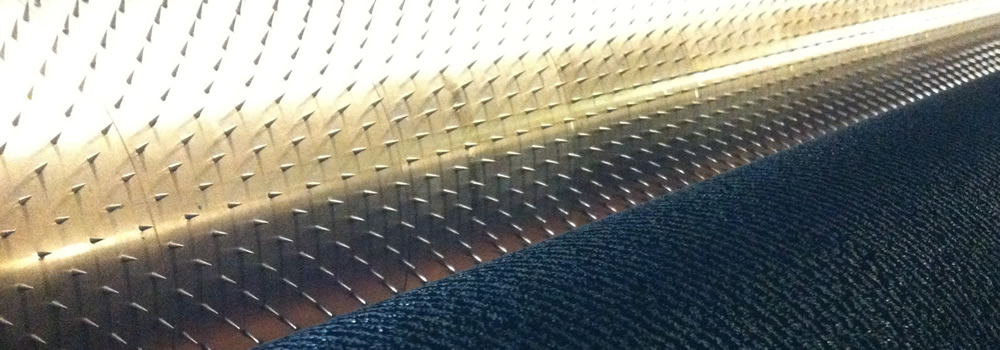

Grooved Rolls

Machined to match/mate up with the pins or blades that are being used. Grooves can vary in width and depth, and must be precision CNC machined in order to match up precisely with the perforating roll. Grooved rollers can be supplied as metal, urethane covered, silicone covered or rubber covered. Positives to grooved rollers are the fact that the pins are essentially in air, there is nothing to wear the pin. Drawbacks are that thinner materials can deflect off the pin tip and cause variation in hole sizes. One also has to mate the pins or blades up to the grooves precisely in order to prevent damage to the pins or blades. Grooved roller do not release particles, however, only work for low perforation density applications.

Airflow Management

- Grooves vent trapped air between the web and roller surface, reducing air entrapment and wrinkles.

- Improves lay-flat quality of films, foils, and laminates.

Reduced Contact Area

- Minimizes friction and drag, especially beneficial for delicate or tacky substrates.

- Lowers heat generation and wear on both the roller and web.

Improved Web Tracking

- Helical or spiral grooves create a directional effect that stabilizes web movement and minimizes wandering.

Enhanced Coating and Laminating Processes

- Grooves distribute adhesive, resin, or coatings evenly and prevent bubble formation.

- Ensures consistent quality in bonding and surface treatments.

Contact us for more info on Grooved Rolls

Stewarts Anvil Rolls Provide Accurate Support and Control

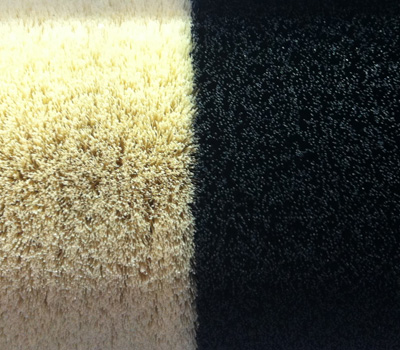

Felt Covered Rolls

Felt covered rollers can be used for both hot and cold perforating applications, and are an inexpensive solution as a backup anvil roller.

Positives of felt technology is that felt rollers have great chemical resistance properties, excellent abrasion resistance, and its decent temperature resistance. Drawbacks are that the surface of the roller is not accurate enough for fine perforating. Note that covered rollers can particulate, so it is recommended that the user have particulate detection systems downstream of the rollers.

Felt covered rollers are commonly used in 3D perforating applications where not just the hole size is important, but also the geometry of the volcano that is created by the pin

The felt covered roller takes the impression of the tip of the pin and becomes the female mold, creating the 3D perforation and therefore creates a texture on the surface of the material being perforated.

In a similar manner, felt covered rollers are excellent anvil rollers for embossing applications. Density, hardness, and thickness of felt can be tailored for traction, cushioning, or thermal needs. Rollers can be precision-ground for smoothness or left with a softer nap, depending on application.

Contact us for more info on Felt Rolls

Fluted Rolls

Fluted Rolls are precision-engineered rollers featuring machined grooves or channels (flutes) across their surface. They are widely used in converting, embossing, laminating, and web-handling applications where materials need to be gripped, guided, aerated, or embossed without slippage. The flute geometry can be customized—straight, spiral, or helical—to achieve specific handling, spreading, or surface-modification effects on the web.

Flute Patterns:

- Straight flutes for general web traction and material aeration.

- Helical or spiral flutes for web spreading and wrinkle reduction.

- Custom flute patterns for embossing or functional texture creation.

- Flutes increase traction by reducing contact area while concentrating grip on the web.

- Air channels created by flutes help prevent air entrapment during lamination or winding.

- Helical patterns apply lateral forces, guiding or spreading the web for improved alignment.

- Can emboss, texture, or mechanically modify the surface of certain substrates when paired with a mating roll.

Contact us for more info on Felt Rolls

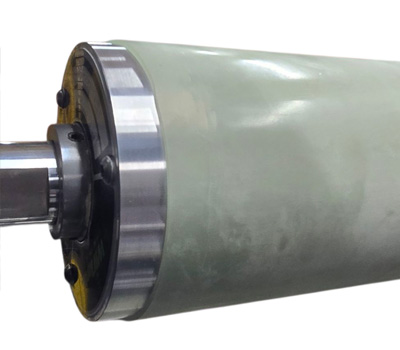

Idler Rolls

Stewarts of America manufactures and supplies a variety of anvil rolls, brush rolls, grooved rolls, felt covered rolls, urethane rolls, and idler rolls for industrial applications.

Stewarts of America also offer high wearing coatings such as chrome, tungsten carbide and ceramic, and high release coatings such as fluoro-polymers, and protective roll covers.

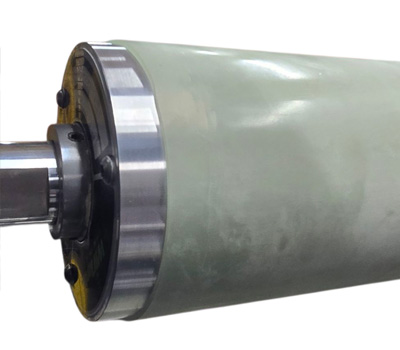

Stewarts of America manufactures lightweight idler rollers with internal or external bearings. Idlers can be made with grooves going in the machine direction or the cross web direction for air ventilation, which allows the web to lay flat on the roller to help resist wrinkling and air trappage.

Idler rollers are passive, non-driven rollers used extensively in converting machinery to guide, support, and control web materials such as films, foils, papers, textiles, and nonwovens. While idler rollers do not impart motion, their precision manufacturing and surface engineering are critical for maintaining web alignment, tension, and quality throughout high-speed converting processes.

Idler rollers can be made as dead shafts or with internal bearings.

Contact us for more info on Idler Rolls

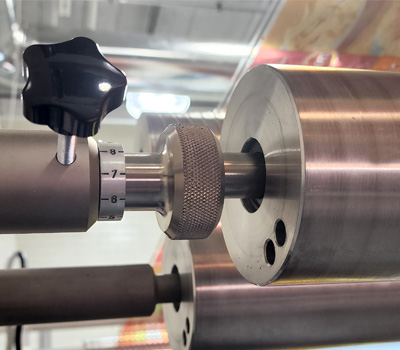

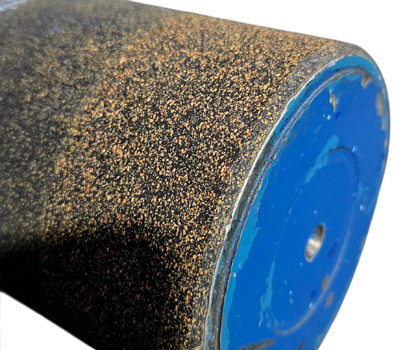

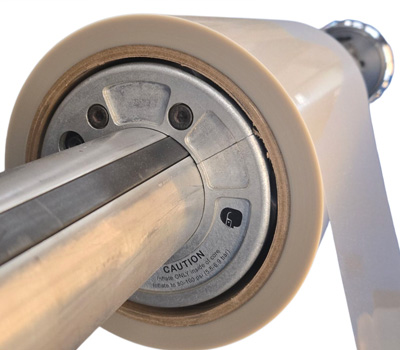

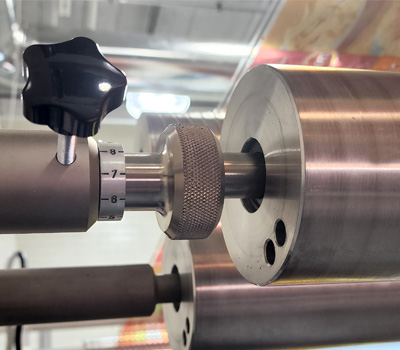

Mechanical Expanding Shafts

Mechanical Expanding Shafts are a core-holding device used in winding and unwinding applications to secure and support rolls of roll based materials. It operates by mechanically expanding gripping elements outward to lock into the inner diameter of a roll core, ensuring secure torque transmission and precise roll alignment during converting processes. These mechanical expanding shafts can also be used as center shafts for pinned rings for cold perforating applications. The shaft features a series of mechanical lugs, strips, or segments mounted along its outer surface. When the activation mechanism (usually a handwheel, Allen key, or end-cam) is engaged, the internal linkage pushes the gripping elements outward. This expansion locks the shaft firmly against the inner diameter of the roll core, holding it securely for rotation. To release, the mechanism is reversed, retracting the elements for easy roll removal, and no need to worry about deflation failure.

This technology can be utilized with Stewarts of America

HIDE-A-SPIKE™ perforating technology that allows a pinned perforating roller to be converted into an idler by retracting the pins.

Contact us for more info on Mechanical Expanding Shafts

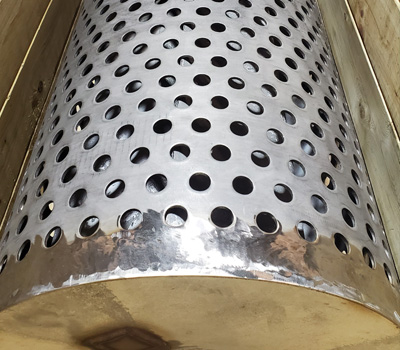

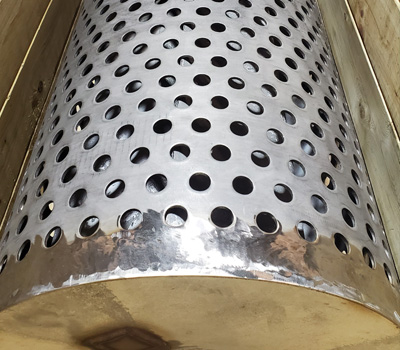

Perforated Sheet Rollers for Calander / Calandar Rolls + Condenser Rolls

Calender rolls are precision-engineered rollers used in converting industry to apply controlled pressure, heat, and surface finish to web-based materials. They are integral to calendering machines, where two or more rolls work together to smooth, compress, emboss, or polish a substrate. Calender rolls are designed to deliver consistent nip pressure, maintain tight tolerances, and ensure uniform product thickness and surface quality.

Reasons for Perforation in Calendar Rolls

Air / Steam Flow Control

- Perforations can be used to circulate hot air, steam, or cooling air through the roll face.

- This helps manage temperature uniformity across the nip, important in heat-sensitive films, textiles, or rubber sheets.

Embossing & Texturing

- Perforated surfaces can be used to imprint patterns, textures, or micro-holes into substrates (e.g., breathable films, hygiene products, filtration media).

- This creates functional surfaces (airflow, absorbency, decorative finishes).

Web Release / Air Evacuation

- When processing lightweight or sticky webs, trapped air in the nip can cause wrinkling or poor contact.

- Perforations allow air evacuation, improving web contact and reducing bubbles or defects.

Moisture Removal

- In paper, textile, or nonwoven calendaring, perforated rolls can be linked with vacuum systems to extract residual moisture from the web while applying pressure.

Weight & Thermal Efficiency

- In some designs, perforated roll shells reduce overall roll weight and allow faster heating/cooling response, improving process efficiency.

Uniform Fiber Distribution

- In nonwoven and textile production, suction through the perforations ensures fibers are evenly layered and held in place. This prevents clumping, thin spots, or uneven surfaces in the finished web.

Condenser rolls are specialized rotating cylinders designed for handling lightweight fibrous webs, such as in nonwoven production, textile processing, and paper making. Their primary function is to condense, support, and transfer delicate webs without damaging or disrupting fiber distribution. By maintaining stable airflow and uniform contact across the web, condenser rolls ensure smooth downstream processing and consistent product quality.

Contact us for more info on Pinned Spreader Rolls

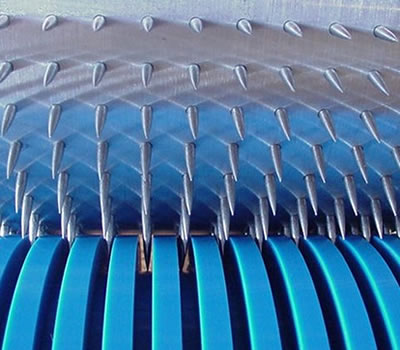

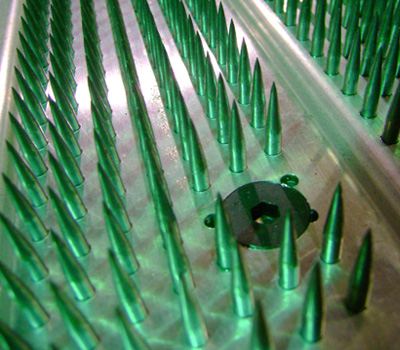

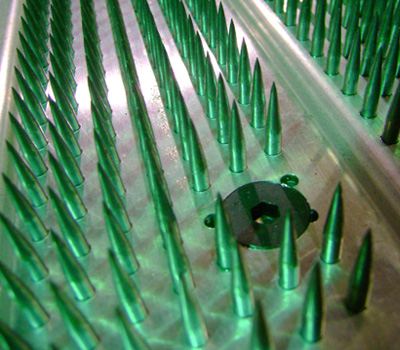

Pinned Spreader Rolls

A pinned roll spreader is a web-handling device designed to remove wrinkles, separate slit lanes, and improve material flatness in converting processes. Instead of a smooth or bristled surface, the roller is covered with a dense array of small, evenly spaced pins or needles. These pins lightly engage the surface of the web, providing both traction and controlled lateral displacement. The pinned rings on the spreader roller are often tilted, so that the material is pulled tight laterally as it passes over the roller. Pinned rollers provide a much stronger grip for tough or slick materials as they provide more positive traction and engagement with the material than other methods of material spreading.

Contact us for more info on Pinned Spreader Rolls

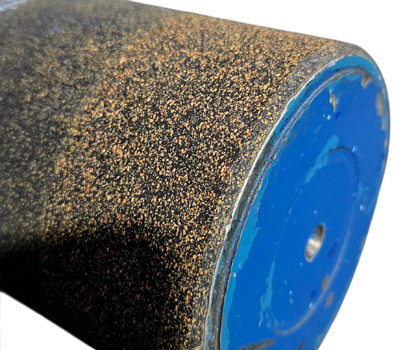

Raising Fillet Rolls

Stewarts of America offer raising fillet rollers, also known as flexible card clothing, metallic card clothing, yarn raising fillet, velvet fillet, wool fillet, fancy fillet, tiger fillet, carrier fillet or scattering fillet.

Round or square wires, in bright, galvanized, tinned or stainless steel finishes. Fillet bases can be made from red rubber, cushion rubber, felt or leather. Chisel, sharp taper, pointed or mushroom style tips. Fillet rollers can be used for a number of texturing, finishing, cleaning and perforating applications. Stewarts of America also make hand tooling from raising fillet for the textile industry.

Raising fillets used primarily in textile finishing and select converting processes to enhance surface texture, improve hand-feel, or modify material appearance. They are applied to rollers or cylinders to create a controlled abrasion effect on the web surface, raising fibers in textiles (napping or sueding) or providing micro-texturing in specialty converting applications. In textiles, raising fillets lift fibers to create a soft, warm feel (flannel, fleece, sueded finishes).

Contact us for more info on Industrial Raising Fillet Rolls

Sponge Covered Rolls + Foam Covered Rolls

Foam Covered Rollers have a resilient foam covering bonded to a core. These rollers are used when handling, cushioning, and controlled contact pressure are required. The foam layer provides a combination of softness, flexibility, and surface compliance that protects delicate substrates while maintaining reliable web control. Foam covers are for a limited amount of applications due to the fact is does wear quickly and has a low chemical and temperature resistance.

Sponge Covered Rollers are specialized rollers featuring a compressible sponge layer bonded to a core. They are designed for applications requiring gentle handling, controlled pressure distribution, cushioning of delicate substrates or wetting applications where distribution of inks, dyes, adhesives or other liquids is a factor. Sponge coverings, have open-cell or semi-open-cell structures and provide enhanced absorption, grip for materials with irregular surfaces, and surface compliance compared to solid coverings such as rubber or polyurethane.

Stewarts of America offer Industrial Sponge Rollers in three colors:

- Gray Sponge - for applying solvent stain on smooth, hand scraped, or beveled substrates.

- Red Sponge - this compound is designed to allow the stain to ride on the surface of the sponge and release on to the surface of wood and other porous materials.

- Blue Sponge - the latest generation of sponge material developed as a hybrid roller. This sponge is resistant to solvents, water based AND 100% UV stains and other liquids. This special compound is designed to allow the liquid to penetrate into the sponge before being squeezed onto the surface of the product.

- The thickness and porosity of any of these sponge coatings can be varied to suit application requirements.

Contact us for more info on Sponge Covered Rolls

Sticky Roller

A sticky roller system is a contact-based web cleaning solution designed to remove loose particles, dust, fibers, and surface contaminants from a continuously moving web. By using a tacky roller surface, the system captures debris directly from the web without damaging or altering the substrate. The sticky roller is brought into light contact with the moving web. As the web passes across the roller, particles adhere to the tacky surface of the roller instead of remaining on the substrate. The roller is then continuously or intermittently cleaned using an adhesive sheet, cleaning blade, cleaning roller or washing unit.

Single-Sided Cleaning – One sticky roll cleans one surface of the web.

Dual-Sided Cleaning – Sticky rolls above and below the web clean both surfaces simultaneously.

Continuous Systems – Use peel-off adhesive sheets or replaceable rolls for uninterrupted production.

Sicky rolls can be used in a verity of cleaning applications:

Film & Foil Converting – Removes dust and static-attracted debris from plastic films, aluminum foils, and metallized substrates.

Paper & Board Processing – Cleans fine dust and fibers that could interfere with coating or printing.

Lamination Lines – Prepares surfaces by ensuring contaminant-free contact between layers.

Printing & Packaging – Improves ink adhesion and reduces print defects.

Cleanroom Converting – Critical in electronics, medical, and optical applications where surface contamination cannot be tolerated.

Contact us for more info on Sticky Rollers

Urethane, Rubber and Silicone Covered Rolls

Covered rollers can be a great solution to your perforating application.

Positives or covered rollers can be re-covered when they wear and can be used in a wide variety of perforating applications. Covered rollers are generally only good for fine perforating applications however, as the surface of the roller has to be soft enough to accept the pin, but hard enough to resist the picking action of the pin. Note that covered rollers can particulate, so it is recommended that the user have particulate detection systems downstream of the rollers.

5 durometer shore A up to 90 shore D hardness available with grooving, spiral ruling, spreader, diamond threading and crowning capabilities.

Rubber-covered rollers are among the most widely used rollers in converting, printing, laminating, and packaging industries. By applying a durable rubber or elastomer covering to a precision-engineered roller core, these rollers combine strength, traction, and surface compliance. They are critical for providing grip, pressure, or controlled release in web handling systems.

Silicone-covered rollers are specialized industrial rollers used in converting, laminating, coating, and heat-assisted processing applications. The silicone elastomer covering provides a unique combination of high-temperature resistance, non-stick properties, and durability, making these rollers ideal for handling adhesive-coated, heat-sensitive, or tacky substrates.

Polyurethane-covered rollers are high-performance rollers widely used in converting, laminating, slitting, coating, and packaging applications. The polyurethane (PU) covering combines excellent abrasion resistance, chemical durability, and load-bearing capability with a customizable range of hardness. These properties make PU rollers especially valuable in demanding web-handling operations where both toughness and precise surface control are required.

Contact us for more info on Urethane Rolls

A Global Leader in Technical Textiles and Precision Perforating