Converting Technologies

Stewarts of America designs and manufactures a multitude of converting machines and accessories.

Proven Expertise in Converting Machinery

Stewarts of America design, engineer, and manufacture perforating tooling, perforating machinery, converting machinery and accessories. With decades of industry experience, we have established a reputation for delivering robust, reliable, and highly customized solutions for companies processing films, foils, papers, composites, nonwovens, technical textiles and other materials. Our tooling and equipment is engineered with precision, designed for longevity, and supported by our commitment to innovation and customer service.

Complete Line of Converting Equipment

Stewarts of America has the capability to design and build every stage of a converting process, offering turnkey solutions or individual machines tailored to specific requirements. These systems can be an inch wide for narrow web and R&D applications through to 5000mm wide for nonwoven and other specialty applications.

Tailored Engineering & Custom Solutions

What sets Stewarts of America apart is the ability to customize while basing machinery on field proven designs. Stewarts of America listen to customer requirements, and engineer solutions that integrate seamlessly into existing operations. Whether it’s a standard slitter / rewinder, a specialized perforating system, or a full turnkey line, our team delivers equipment that optimizes efficiency, reduces downtime, and improves material yield.

Built for Reliability and Performance

- Precision Manufacturing: All critical components are designed and built in-house at our U.S. facilities, ensuring strict quality control.

- Durability: Heavy-duty construction and premium materials extend equipment life and minimize maintenance.

- Integration: Our converting machinery can be supplied as standalone units or fully integrated into existing lines.

- Global Support: We serve customers worldwide with installation, training, spare parts, and ongoing service.

Your Partner in Converting Solutions

From unwinds and rewinds to slitters, perforators, rollers, and beyond, Stewarts of America offers a complete range of converting machinery backed by decades of proven performance. We are more than a manufacturer—we are a partner in innovation, helping companies improve productivity, product quality, and profitability.

When precision and reliability matter, Stewarts of America is the trusted source for perforating & converting solutions.

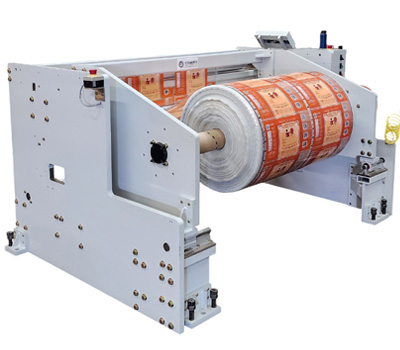

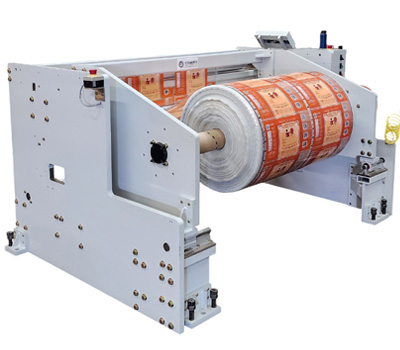

Unwind Stands

An unwind stand (aka unwinder or payoff stand) supports a parent roll of material and dispenses it to downstream converting equipment. Unwind stands enable controlled unwinding of flexible materials.

Stewarts of America build unwind with manual or automatic brake systems, tension controls, safety checks and web guides as options. Unwinds can be separated from rewinds so that processing equipment can be fitted in between, or sold by themselves for sheeting applications.

Contact us for more info on Unwind Stands

Rewind Stands

A rewind stand (aka rewinder or take-up stand) is a mechanical unit designed to collect and wind material into rolls after it has been processed through upstream converting equipment.

Stewarts of America rewinders enable controlled, consistent rewinding of material with precise tension, alignment, and roll formation. Rewinds can be separated from unwinds so that processing equipment can be fitted in between, or sold by themselves for roll from sheet applications.

Contact us for more info on Rewind Stands

Unwind/Rewind

An Unwind/Rewind unit is a dual-function web-handling system used in continuous roll to roll material processing applications to unwind material from a parent roll and subsequently rewind it into a finished roll. It is commonly used in the converting, perforating, printing, laminating, slitting, coating, and inspection industries for processing flexible web materials.

Stewarts of America have the ability to make the unwind rewind system as simple and as complex as needed for the process. With available state of the art tension systems, dancer arms, sensors, brakes, S wraps and lay on rollers to ensure smooth and efficient processing for the material being converted.

Contact us for more info on Unwind/Rewind Equipment

Mini Machinery for Benchtop/R&D Applications

Stewarts of America design and build compact, laboratory-scale equipment, engineered for narrow webs, or the testing, development, and prototyping of sheet, film, or web-based materials. These systems replicate industrial processes on a smaller scale and provide precise control over parameters like tension, speed, temperature, and pressure, making them ideal for formulation trials, material evaluation, and pilot or full scale production.

Stewarts of America have the ability to take any of our large scale equipment and miniaturize it.

Contact us for more info on Unwind/Rewind Equipment

Sheeter

Sheeters can take a sheet and cut it into smaller pieces, or roll fed material and create sheets by either rotary or vertical blade cutting. Sheeters can be made to be simple manual units, or complete automated units that have automated measuring and cutting systems.

Rotary Shear Knives (Tangent or Wrap Shear): Provides continuous, high-speed cutting with minimal dust. Rotary Fly Knives: Suitable for thin films and lightweight materials.

Guillotine / Cross-Cutting Blade: A straight blade that cuts across the web, ideal for thicker or rigid materials. Cutting is precisely timed with line speed using servo or electronic synchronization.

Contact us for more info on Sheeter Equipment

Stacker

Stacker is a mechanized system designed to collect, align, and stack individual sheets or products into uniform piles after they have been cut, processed, or conveyed from upstream equipment. Shingle/Overlap Conveyor: Staggers sheets for stacking.

Pile Stacking System: Sheets drop or are placed directly into a pile on a platform. Reciprocating Tray or Gripper System: Places sheets individually in position. Once the stack reaches the desired height or count, it is automatically lowered, removed, or transferred for packaging, palletizing or another downstream process.

Contact us for more info on Stacker Equipment

Nip Length Measuring

Nip Length Measuring is the process of quantifying the length and sometimes the alignment of a material being processed. The material is controlled by an adjustable nip, formed between two rollers. Measuring can be as simple as a digital readout, or the data can be used in conjunction with other processes such as guillotines. Coated, texturized or pinned rollers can be used in the nip to ensure no slippage of the material in the nip system.

Contact us for more info on Nip Length Measuring Equipment

Manual Rotary + Vertical Press Applications

The manual rotary punch and vertical punch units are designed for perforating, or embossing materials. Both rotary and vertical devices rely on mechanical force applied through a hand-operated mechanism, making them suitable for low- to medium-volume converting processes, laboratory use, or applications where precision punching is required without the need for powered systems. They offer Low-cost, energy-free operation (manual, no compressed air or motors needed) but with a high control and precision for small runs or specialized applications. They are simple to maintain due to mechanical-only construction. They are portable for lab, in factory or field use. Limitations are that they are not suitable for very high-volume production, operator effort required, leading to slower cycle times. Punch size and width are limited.

Contact us for more info on Manual Rotary + Vertical Press Applications

Razor Slitter

A razor slitter is a precision cutting device attachment used to slit continuous rolls or webs of flexible materials into narrower widths by passing the material over stationary razor blades. It is widely used in converting industries. Stewarts of America razor slitting units have blade holders that are easy to move, and lock in place to give a precision cut, and are designed for ease of maintenance. There are a few types of razor slitting available.

Contact us for more info on Razor Slitters

Razor in Groove

It employs razor blades aligned with grooved anvils to achieve clean, straight cuts with minimal dust or deformation, making it well-suited for delicate substrates.A stationary razor blade is positioned directly into a matching groove on a hardened anvil roll or support roller. As the web passes through the nip between the blade and groove, the material is sheared cleanly. The groove stabilizes the cut and prevents lateral blade movement, ensuring high cut accuracy even at high line speeds.

Contact us for more info on Razor in Groove

Razor in Air

Instead of cutting against a groove or anvil, the razor blade is suspended in “free air,” supported only by the tension of the moving web. This method is widely used for thin plastic films and other lightweight substrates where a precise, clean cut is required at relatively low cost. A stationary razor blade is mounted in close proximity to the moving web. As the web passes over the blade, the tension of the web presses it against the cutting edge, creating a clean slit. Because there is no support roll or groove beneath the cut, web tension and stability are critical to maintaining cut quality.

Contact us for more info on Razor in Air

Crush/Shear/Score Slitter

The crush shear slitter operates by pressing a male slitting blade against a female anvil blade. The web material passes through the nip formed between these blades. The opposing action shears the material precisely along the blade edge, producing clean, burr-free slit edges. This cutting method combines mechanical shearing and crushing forces to ensure high-quality cuts, especially for thicker or multi-layer materials.

Stewarts of America crush/shear slitting modules can be easily added to an existing machinery line.

Contact us for more info on Crush/Shear/Score Slitters

Tangent Shear Slitting

Uses a male (top) knife and a female (bottom) knife arranged in a tangent contact setup, where the cutting action occurs at the point where the two circular knives meet. The method produces a clean, accurate cut by shearing the material in the same way as scissors. The male knife rotates in contact with the female knife at a tangent point. The web passes through this nip, and the shearing action between the two sharp edges separates the web into narrower widths. Correct overlap and side pressure between the knives are essential to maintain cut quality and extend blade life.

Contact us for more info on Tangent Shear Slitting

Burst Shear Slitting

Unlike rotary shear slitting, which uses paired male and female circular knives, burst shear slitting employs a single rotating disk blade pressed against a hardened anvil roll or support surface. The material is “burst” or sheared apart as it is drawn through the cutting zone. While less accurate than true shear slitting, it is also a more economical method.

Contact us for more info on Burst Shear Slitting

Wrap Shear Slitting

Wrap Shear Slitting is a high-precision slitting method where the web is wrapped partially around a female (bottom) knife before being cut by a male (top) knife. The wrap angle ensures firm support and stability of the web during the cut, producing exceptionally clean and accurate slits, especially on difficult or delicate substrates. The web makes partial contact (typically 5°–30° of wrap) around the rotating female knife. The male knife engages from above, cutting against the female knife’s edge in a true scissor action. The wrap stabilizes the web, reduces flutter, and keeps the web under tension at the cut point, resulting in superior edge quality.

Contact us for more info on Wrap Shear Slitting

Stewarts of America also offer accessories for converting such as:

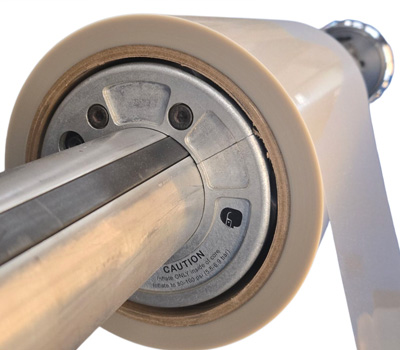

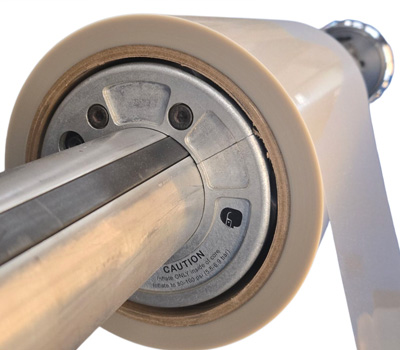

Safety Chucks

Safety Chucks are used to secure and drive shafted rolls in web handling and converting machinery. It provides safe, quick engagement and disengagement of the roll shaft while transmitting torque from a motor or brake. The safety chuck consists of a housing with a slotted opening designed to accept the journal or shaft end (commonly square or diamond-shaped). The chuck can be opened to insert or remove the shaft, then closed to securely lock it in place during operation. Power transmission occurs directly through the safety chuck to the shaft, allowing the roll to be driven or braked as needed. Tilting or sliding safety checks are available.

Contact us for more info on Safety Chucks

Air Expanding Shafts

A mechanical device used to grip and hold rolls of material in converting machinery. It uses pneumatically actuated elements—typically lugs, bladders, or strips—that expand to grip the core of a roll securely for high-speed rotation or tensioned web handling. These air shafts can also be used for center shafts for cold pin perforating applications.<

br>

Lug type – metal or rubber lugs provide strong point contact.

Leaf type – segmented leaves provide full circumferential grip. Strip/rubber tube type – continuous expansion for light to medium loads.This technology can be utilized with Stewarts of America

HIDE-A-SPIKE™ perforating technology that allows a pinned perforating roller to be converted into an idler by retracting the pins.

Stewarts also offer shaft adapters.. A cost-effective and practical solution for adapting a standard air shaft to accommodate larger diameter cores. Built from high-quality materials, our chuck adapters are designed to withstand demanding workloads. Their heavy-duty construction ensures reliable performance in both rewind and unwind applications, making them ideal for handling rolls with metal, fiber, or cardboard cores.

Contact us for more info on Air Expanding Shafts

Mechanical Expanding Shafts

Mechanical Expanding Shafts are a core-holding device used in winding and unwinding applications to secure and support rolls of roll based materials. It operates by mechanically expanding gripping elements outward to lock into the inner diameter of a roll core, ensuring secure torque transmission and precise roll alignment during converting processes. These mechanical expanding shafts can also be used as center shafts for pinned rings for cold perforating applications. The shaft features a series of mechanical lugs, strips, or segments mounted along its outer surface. When the activation mechanism (usually a handwheel, Allen key, or end-cam) is engaged, the internal linkage pushes the gripping elements outward. This expansion locks the shaft firmly against the inner diameter of the roll core, holding it securely for rotation. To release, the mechanism is reversed, retracting the elements for easy roll removal, and no need to worry about deflation failure.

This technology can be utilized with Stewarts of America

HIDE-A-SPIKE™ perforating technology that allows a pinned perforating roller to be converted into an idler by retracting the pins.

Contact us for more info on Mechanical Expanding Shafts

Blades

Stewarts of America offer a wide range of blades for converting. Razor blades, static mounted and rotary. Blades for Slitting (static or rotary), Cross Cutting (fly knives, guillotine blades), Perforating (Creating patterns of holes or tear lines), Trimming or Edge removal and Granulating/Shredding, amogst other applications such as packaging, printing, food processing, laminating, converting, and more.

From chopping, perforating, scraping, folding, slicing, sealing, and shearing to general cutting needs, we deliver blades engineered to match your exact requirements. Stewarts understand how to craft machine knives that are consistently razor-sharp, burr-free, and built for performance. Looking for a unique cut pattern or ways to extend blade life and durability? Our team is ready to work with you to optimize your industrial blades and help you achieve your production goals.

Contact us for more info on Blades

At

Stewarts of America, we engineer and manufacture high-performance industrial rolls designed to keep your converting and processing operations running at peak efficiency. Whether your application requires precision winding, spreading, laminating, perforating, or web handling, our rolls are built to deliver unmatched reliability, consistency, and longevity.

Crafted with premium materials and precision machining, our rolls are designed to handle everything from delicate films to heavy-duty substrates. Options include rubber-covered rolls, cork rolls, bow rolls, brush rolls, and more — each tailored to solve specific challenges like web spreading, tension control, or material finishing.

With over 150 years of industry expertise, we don’t just supply rolls; we provide engineered solutions. Our team works closely with customers to design and manufacture rolls that fit seamlessly into their process, reduce downtime, and improve output quality. When you choose Stewarts of America, you’re choosing

durability,

precision, and

performance — backed by a company trusted worldwide in the converting, packaging, and processing industries.

Stewarts of America rolls: built to perform, built to last.

A Global Leader in Technical Textiles and Precision Perforating